Reality Capture and Digital Twin

If you could make business critical decisions with greater certainty, increase the effectiveness of your planning and design process, achieve quicker installation and improve the efficiency of live operations, wouldn’t you take that option?

Plowman Craven can provide Kinematic Scanning which provides a rapid, repeatable, cost effective and accurate asset management solution by turning your facility into digital reality. Collecting as-built data that is available almost immediately provides the ability to extract and share information in real time.

20%-30% cost savings in efficiency gains

Up to 10 times faster than terrestrial scanning

Reduces time and cost for late changes and planning errors

Reality Capture for Asset Management

A digital twin can provide real advantages:

- Enables an understanding of the current facility and its asset condition in 3D or 2D

- Ability to include all stakeholders visually, remotely and interactively, working in real time

- Rapid re-scanning keeps the data right up to date

Having access through either a website portal and interactive viewing tool or on your main system, you will have flexibility to:

- Take direct measurements

- Download and extract 3D data, create models, or 2D CAD

- Geotag points of interest

- Include locational optimisation and route planning

- Ensure multi-stakeholder involvement in a virtual digital facility

Operating Nationwide or Worldwide?

Operating with a digital twin allows greater flexibility and response. Managing multi-site operations has its difficulties but having the ability to remotely visit a site to inspect or compare assets has considerable advantages in relation to both time and cost.

The ease and speed of our reality capture techniques means change or a refit can be easily added to the main dataset. Regular re-surveys assure that the data is always up-to-date.

Efficient Management

A digital twin supports efficient and lean management. Having accurate data available to all stakeholders means quick and informed decision making enabling best practice and protocol adaption. An interactive viewing tool allows transfer of geo-spatially referenced information and tagging equipment or locations with meta-data provides additional information on items such as specifications and Health and Safety protocols.

Benefits

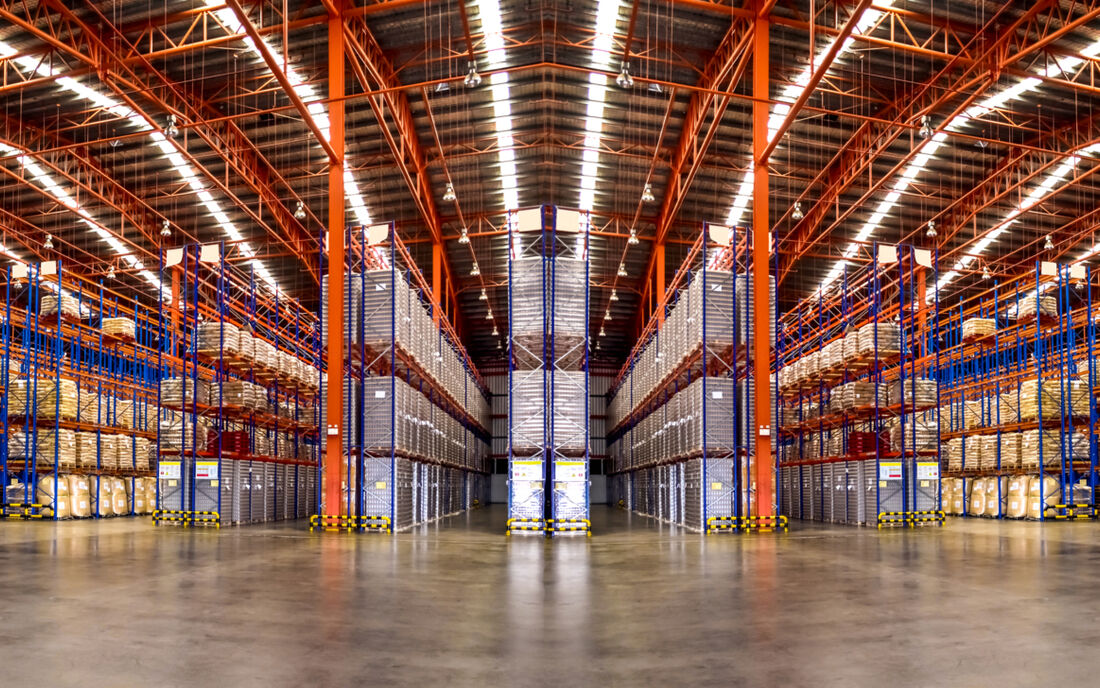

Reality capture offers real advantages to warehouse, logistics, automation facility and operations managers, designers and suppliers. It can also be easily applied to bespoke robotic and automation projects.

- Accurate, consistent and timely data that is kept up-to-date in a cost-effective way

- Improves collaboration with all stakeholders

- Facilitates more informed decision making and market reaction

- Reduces re-works or late design adjustments

- Provides a greater understanding and information of all facilities

- Accommodates best practice

- Reduces travel through remote access to reality

- Multi-stakeholder access both in the office or ‘on the go’ on the shop floor

- Geo-spatially tag items for reference or instruction

- Reduces project timelines

- Increases employee productivity

- Offers data that supports space optimisation

- Effective management of geo-spatial data across multiple sites

How Can We Help?

Let’s discuss your requirements and see how our expertise in Reality Capture and Digital Twin can help on your next project.

Plowman Craven has 60 years’ experience providing integrated measurement and consultancy services to the property and infrastructure markets.